DTC optimization: Difference between revisions

| Line 20: | Line 20: | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

! Material !! Thickness !! <math>\Delta t / \sqrt | ! Material !! Thickness !! <math>\Delta t / \sqrt{12}</math> !! Resolution !! Excess straggling !! Pre-straggling resolution !! Layers for 230 MeV + <math>5\sigma</math> | ||

|- | |- | ||

| Al || 2 mm || 1.5 mm || 4.16 mm || 6.1% || 1.38 mm || 67 | | Al || 2 mm || 1.5 mm || 4.16 mm || 6.1% || 1.38 mm || 67 | ||

Revision as of 12:22, 22 March 2017

Geometry and segmentation optimization of the Digital Tracking Calorimeter

Optimization philosophy

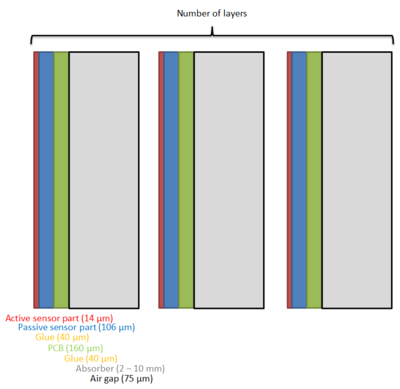

Geometry

Materials

Software

The software for this project is Gate installation and the DTC toolkit. For a complete guide to use the software for optimization, see the page Software for design optimization.

Results

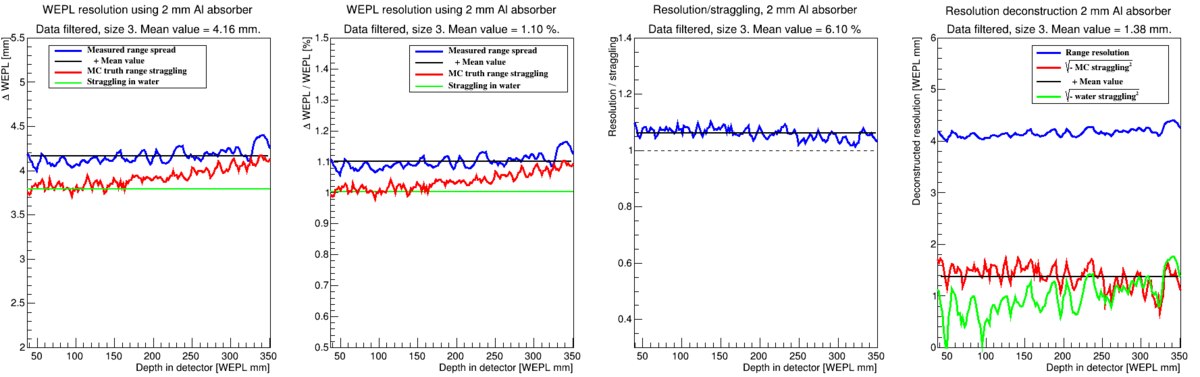

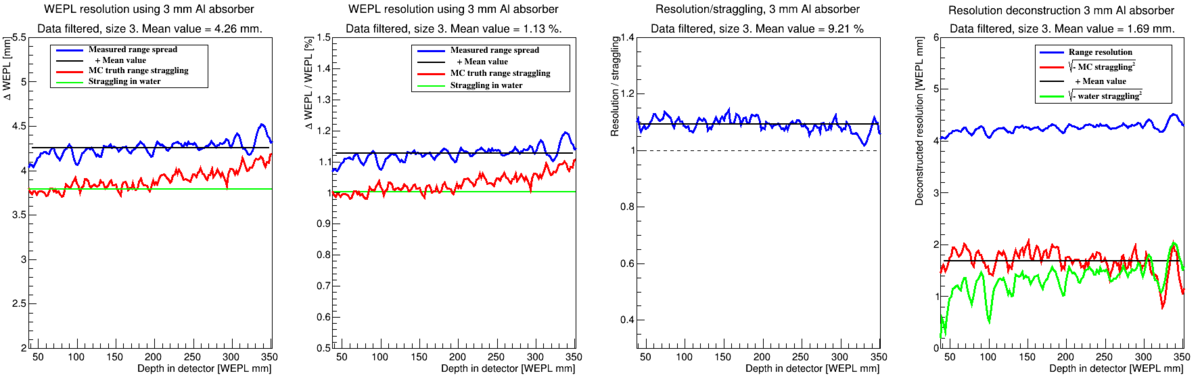

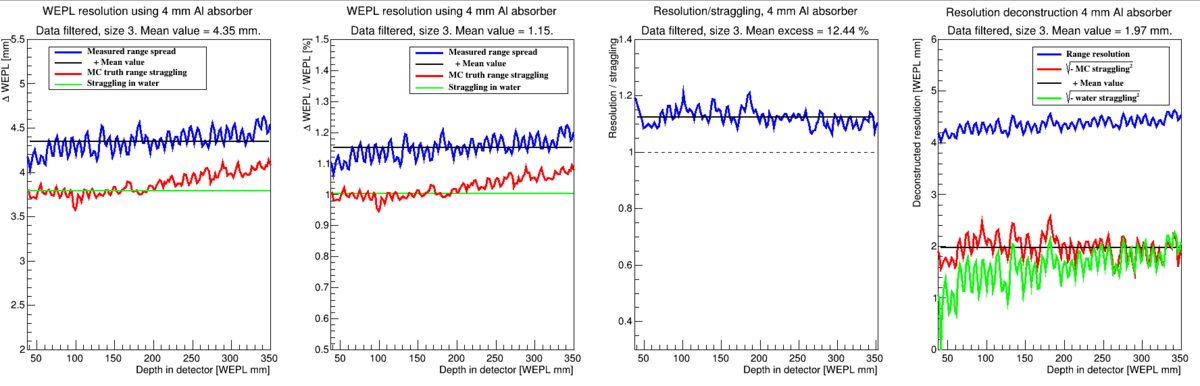

All following values are given in units of Water Equivalent Thickness!

Pre-straggling resolution is the contribution to the total resolution from the detector smearing. This is calculable because we know the range straggling from Monte Carlo simulations, and the pre-straggling resolution is a subtraction in quadrature.

| Material | Thickness | [math]\displaystyle{ \Delta t / \sqrt{12} }[/math] | Resolution | Excess straggling | Pre-straggling resolution | Layers for 230 MeV + [math]\displaystyle{ 5\sigma }[/math] |

|---|---|---|---|---|---|---|

| Al | 2 mm | 1.5 mm | 4.16 mm | 6.1% | 1.38 mm | 67 |

| Al | 3 mm | 2.1 mm | 4.26 mm | 9.2% | 1.69 mm | 48 |

| Al | 4 mm | 2.7 mm | 4.35 mm | 12.4% | 1.97 mm | 39 |

| Al | 5 mm | 3.3 mm | ||||

| Al | 6 mm | 3.9 mm | ||||

| Al | 7 mm | 4.5 mm |