DTC optimization: Difference between revisions

| Line 12: | Line 12: | ||

== Results == | == Results == | ||

All following values are given in units of Water Equivalent Thickness! | All following values are given in units of Water Equivalent Thickness! (Except the absorber thicknesses) | ||

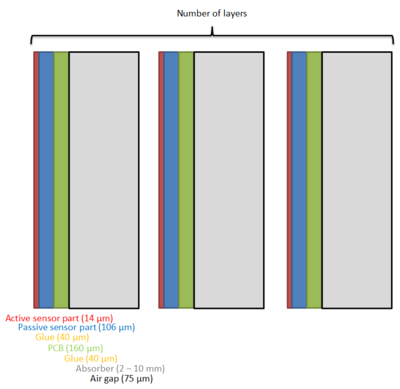

[[How many layers are needed?]] | [[How many layers are needed?]] | ||

| Line 20: | Line 20: | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

! Material !! Thickness !! <math>\Delta t / \sqrt{12}</math> !! Resolution !! Excess straggling !! Pre-straggling resolution !! Layers for 230 MeV + <math>5\sigma</math> | ! Material !! Thickness !! <math>\Delta t / \sqrt{12}</math> WEPL !! Resolution !! Excess straggling !! Pre-straggling resolution !! Layers for 230 MeV + <math>5\sigma</math> | ||

|- | |- | ||

| Al || 2 mm || 1.5 mm || 4.16 mm || 6.1% || 1.38 mm || 67 | | Al || 2 mm || 1.5 mm || 4.16 mm || 6.1% || 1.38 mm || 67 | ||

Revision as of 12:23, 22 March 2017

Geometry and segmentation optimization of the Digital Tracking Calorimeter

Optimization philosophy

Geometry

Materials

Software

The software for this project is Gate installation and the DTC toolkit. For a complete guide to use the software for optimization, see the page Software for design optimization.

Results

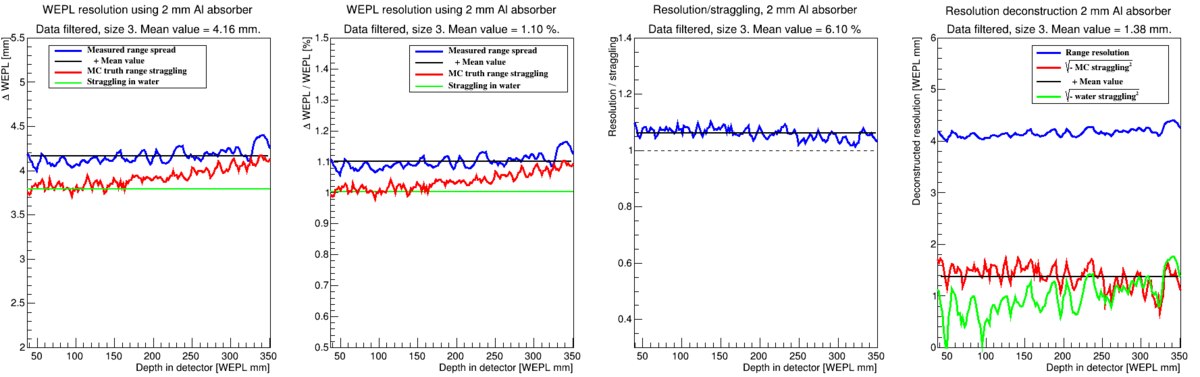

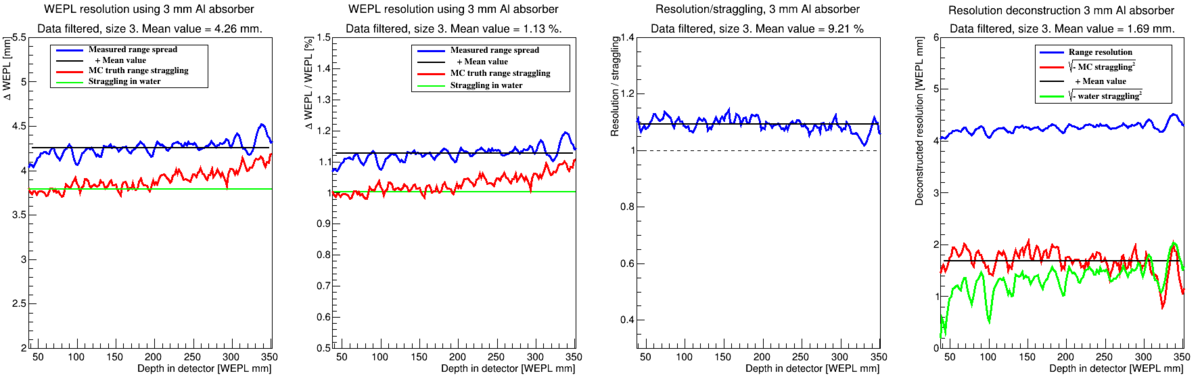

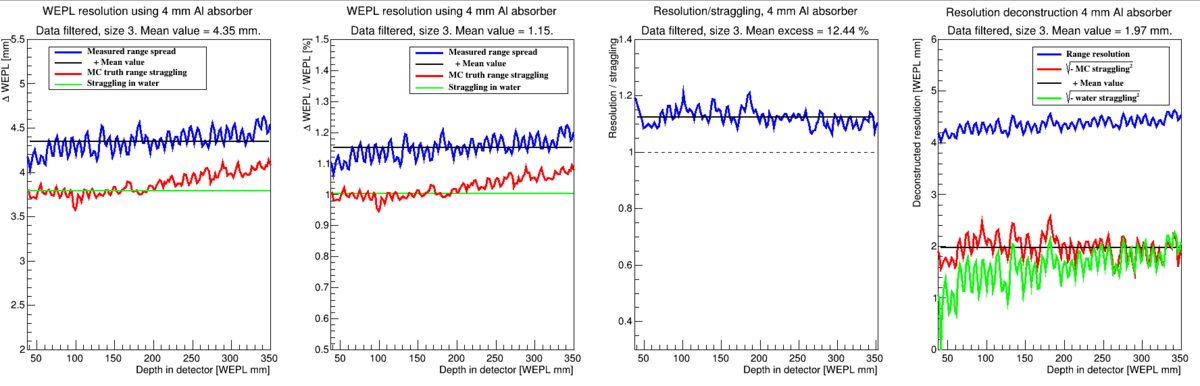

All following values are given in units of Water Equivalent Thickness! (Except the absorber thicknesses)

Pre-straggling resolution is the contribution to the total resolution from the detector smearing. This is calculable because we know the range straggling from Monte Carlo simulations, and the pre-straggling resolution is a subtraction in quadrature.

| Material | Thickness | [math]\displaystyle{ \Delta t / \sqrt{12} }[/math] WEPL | Resolution | Excess straggling | Pre-straggling resolution | Layers for 230 MeV + [math]\displaystyle{ 5\sigma }[/math] |

|---|---|---|---|---|---|---|

| Al | 2 mm | 1.5 mm | 4.16 mm | 6.1% | 1.38 mm | 67 |

| Al | 3 mm | 2.1 mm | 4.26 mm | 9.2% | 1.69 mm | 48 |

| Al | 4 mm | 2.7 mm | 4.35 mm | 12.4% | 1.97 mm | 39 |

| Al | 5 mm | 3.3 mm | ||||

| Al | 6 mm | 3.9 mm | ||||

| Al | 7 mm | 4.5 mm |